Bathrooms face constant exposure to water, steam, and fluctuating temperatures. As with any room with running water, the furniture and other items in a bathroom are subjected to more stress than in dry rooms. This is why you need to find materials that will withstand moisture and extreme temperatures to avoid frequent replacements. While there are many options on the market today, wooden bathroom cabinets have become a firm favourite for their easy-clean functionality, durability, and classic good looks. Vinyl and laminate alternatives often provide a visual wood effect, but they struggle to match the long-lasting appeal of real wood furniture.

Although the material is purely down to personal preference, however, time should be taken to consider some of the factors before making a purchase.

- Moisture Levels: Bathrooms come with moisture in more than one form, from steamy showers to flowing taps. Materials that cannot stand up to such humid conditions will invariably fail in durability. You will notice fungal attacks, swelling, warping, or rotting upon exposure on your pieces. Such degradation will also give an unpleasant look to the furniture and the bathroom.

- Ventilation: Ventilation is essential to a comfortable indoor temperature and air quality. A well-ventilated bathroom can play a key role in reducing moisture levels to some extent. This can help reduce the growth of fungus and moulds, which can attack furniture. Lack of proper airflow can also become an energy efficiency nightmare.

- Aesthetics: You can certainly have the best of both worlds: style as well as moisture protection. Many water-resistant materials like treated hardwoods, stainless steel, and some synthetic materials are durable and come with a pleasing appearance.

- Maintenance: The best kind of furniture materials will usually be moisture-resistant, requiring only minimal maintenance. Such materials will also not easily succumb to mould, mildew, and other water-related problems. This keeps the users stress-free by ensuring a safe and hygienic bathroom environment.

Types of Materials for Bathroom Furniture

There's no building material quite like real wood to bring a warm feeling and create a rustic, traditional look in a home. Even in wood species, the performance and quality of the different materials will be different. Engineered wood floors and furniture are cheaper as well as easier to work with compared to solid wood. You can easily find engineered and hardwood materials for flooring and furniture in the market, made from real wood, with few distinct differences in construction. With newer materials, such as MDF, Chipboard, Particleboard, Metal, and Plastic, the choices have suddenly become vast and varied to suit every pocket and application. Once these differences are explained, it is easy to choose the material that fits your home and budget.

MDF or Medium Density Fibreboard

If you are looking for sturdy, well-finished bathroom furniture minus the exotic cost of wood, then MDF can prove to be a good bet. MDF, or Medium-density fibreboard, is one of the most popular materials used for furniture, as it has an almost never-ending range of applications. Made by fusing sawdust and glue under high heat and pressure, MDF can be moulded into many different shapes. It looks like the real thing but lacks the imperfection of wood, making it high on visual appeal. Cost makes MDF the most popular material in the building of cabinets and furniture, especially when compared to traditional wood, extruded PVC baseboard, or even plywood.

The softness of MDF makes it easy to work with compared to many other types of wood materials. It also won't easily split when machined or nailed, and it won't have any visible surface imperfections and the minor ones can be evened out using sandpaper for a better finish. Plus, it is free of twists or wraps, unlike real wood with natural imperfections. Medium Density Fibreboard is made from recycled wood, including wood dust and shavings, which reduces waste and makes it a more environmentally friendly option than other materials.

Limitations of MDF

MDF may be damaged by moisture and humidity, making it less suitable for use in areas with high humidity or exposure to water. Thus, it is crucial to consider this limitation when installing furniture made from MDF in bathrooms, laundry rooms, or other moisture-prone areas. In such situations, it may not be as durable as other materials, such as solid wood or PVC. MDF flooring can also be a concern in high-traffic areas exposed to high impacts or wear and tear. MDF is prone to chipping and breaking, and although it can be painted, it won't hold a stain. Once damaged, it is difficult to repair, and nail holes are very tough to fill out.

Engineered Wood

Engineered wood or man-made wood has a hardwood or plywood core with a wood veneer layer forming the top surface. It offers increased resistance to heat and moisture compared to solid wood. More versatile and resilient than solid wood, it is also cheaper. Engineered floors have more stability, and are more resistant to everyday wear, buckling, or rippling and also stand up better to moisture and are more stable than solid hardwood.

Drawbacks and Maintenance

As engineered wood has multiple layered compositions, if moisture seeps down into the lower layers, it can compromise the structural integrity of the entire board. The effects may be visible through swelling that can cause the surface to warp. Once the top layer is damaged, it can't be set right by sanding and refinishing, as in the case of solid wood. Engineered wood can also attract mould and mildew if it remains damp for a considerable time. The use of engineered wood bathroom furniture calls for adequate sealing with a good quality sealant. The focus must be on the edges and seams, which are the spots most vulnerable to moisture. We also recommend the use of dehumidifiers or humidifiers, as well as proper ventilation, to maintain a consistent indoor humidity level.

Although no wood product can retard direct water contact, humidity isn't a big issue for engineered wood floors, and these can be easily used over concrete. It is a cheaper and environmentally friendly alternative to solid wood and comes in many different types, such as Plywood, Veneered Wood, Particleboard, HDF(high-density fibreboard), and MDF (medium-density fibreboard)

Here we discuss some of these materials in detail:

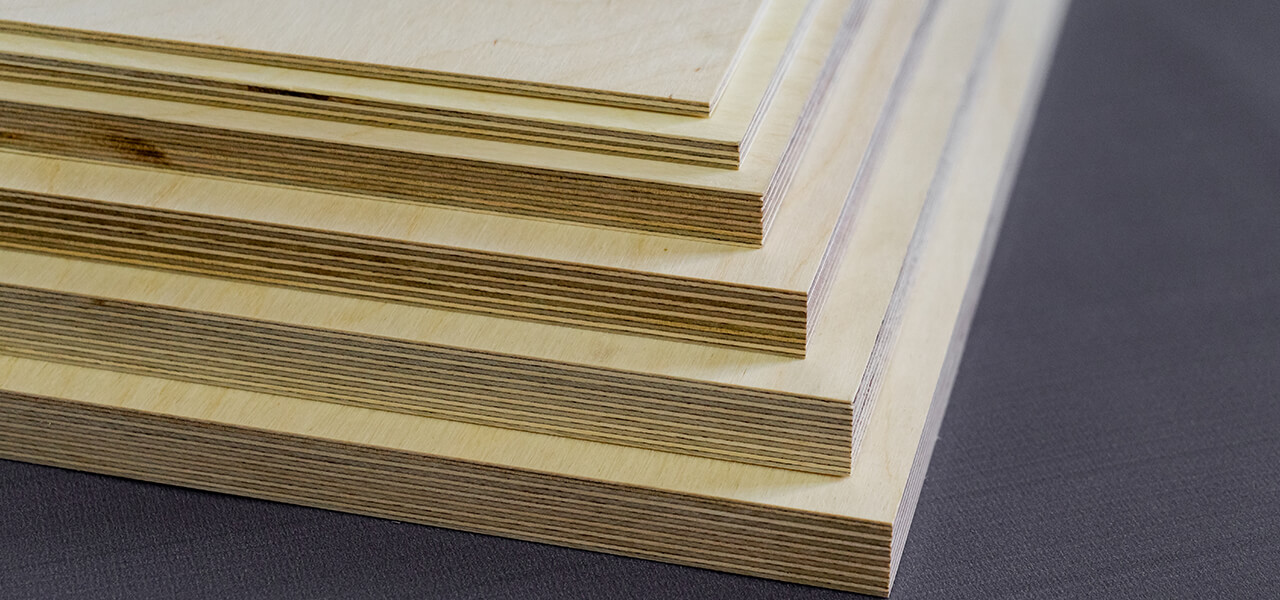

Plywood

Plywood is the most widely used artificial material for furniture. It consists of thin veneers of softwood or hardwood bonded together. The board consists of many different veneers, and the direction of the grain runs alternately to give strength to the board. Plywood comes in various grades and thicknesses, is strong and versatile, and holds its structure even under extreme temperature changes. It can also be sanded for a more refined finish.

Chipboard

Chipboard is the result of wood particles bonded using an adhesive under heat and pressure, which forms rigid and smooth material. Chipboard comes in normal density, medium density, and high density. High-density chipboard is used for worktops and fire doors as it is hard and strong. Veneered Chipboard is widely used for the manufacture of self-assembly furniture, work surfaces, and partitions.

Blockboard

Blockboard has a softwood strip core placed one atop the other and sandwiched between hardwood veneers, bonded under high pressure. Blockboards are stronger than particle boards, thanks to the solid wood core. It is relatively lightweight and can be worked with the use of regular woodworking tools. It can be cut, drilled, and screwed easily. Blockboard is used for making bookshelves, benches, doors, tables, and panelling.

Solid Hardwood Furniture

Hardwood is made from the wood of deciduous evergreen trees, with each species having distinct properties; however, they all have some general properties overall. Hardwoods are extremely durable, making it the material of choice for furniture construction. Their density contributes to their strength, while they have a natural variety in the grain patterns, which gives the wood its unique aesthetic. Hardwood is one of the best woods for carving as it is hard and heavy and well-suited for structural applications. Hardwood timbers last almost forever and, therefore, don't have a detrimental impact on the environment. The best examples of solid hardwood materials are Oak and Teak, while Cedar and Pine are Softwoods.

Oak

Oak offers a high level of resistance to water as it is dense, hard, and non-porous. Oak is also highly shrink-resistant and stands up to wear and tear, making it one of the best woods to use in high-traffic areas and heavy-duty applications. Its distinctive grain pattern gives it an appealing, warm look. Easy to work with, it also finishes well, making it the perfect solid wood for building your bathroom furniture. There is none better than this wood if you are looking to create that timeless and classic interior. On the flip side, Oak is often more expensive, and its weight makes it cumbersome to work, transport, and install. It can be vulnerable to wood-boring insects if not properly treated, so it may need to be treated and resealed regularly to preserve its appearance and durability.

Teak

The use of teak is a rarity in modern times as it is expensive and scarce. Cheaper alternatives like plastic or softwood have taken over in many applications. Its good quality characteristics make it a luxury material with many applications, such as premium bathroom furniture and cabinets for internal and external usage. The wood is rich in natural oils, hard and dense with a tight grain structure, and thus high on durability. It is resistant to warping, cracking, termite attacks, or decay when exposed to moisture over time. Teak is a warm wood that can be varnished, stained, and treated as required.

Cedar

The classic and original choices for furniture were redwood or red cedar. These woods give your furniture pieces a rich colour and natural rustic charm and are relatively free of chemicals. These woods contain tannins and oils that make the wood resistant to decay and insect attacks. Cedar is easy to work and transport as it is less dense and lighter than most other softwoods. Its consistent surface and low density mean it can be easily cut, sawed, nailed, and glued. Plus, it stains and maintains its finish well, so its natural aesthetics can be enhanced in a number of colours.

Pine

Pine is a type of softwood that is very popular in woodworking projects. It absorbs finishes, adhesives, and preservatives much more easily than hardwoods. Pine is not as durable as hardwoods and is not suitable for heavy use or use in high-traffic areas. The wood is usually chemically treated to enhance its lifespan and is referred to as Treated Pine. Treated Pine offers greater resistance to insect and fungal attacks, moisture, and adverse weather conditions. Due to its superior absorption and other inherent properties, treated pine is very durable. Together with its excellent absorption properties, it easily accepts paint, varnish, and oil, making it a good choice for bathroom and kitchen furniture. Softwood species such as Pine grow quickly and thus can be easily 'renewed,' making it a sustainable and economical choice. Pine has a softer surface, but it is still a solid timber. Finished Pine is lightweight, easy to work, finish and transport.

Composites

Composite wood material like plastic lumber is the fastest-growing furniture material sold today. Most of the composite products are made from PE or PVC and come in a wide variety of stylish colours. Some composites are a mix of wood fibres and recycled plastic that stand up well to extreme weather conditions and stains and also won't splinter, warp, split, or decay. The material is lighter and easier to transport and handle than many wood-based materials. It also offers excellent aesthetics as it resembles natural wood and won't need surface coatings or adhesives; therefore, no polluting chemicals are released into the environment. They can provide a high-performance at a competitive price.

Popular composite materials include Particle Board, OSB, Hardboard, Laminated Veneer lumber (LVL), and others that are designed to be strong and durable, with better water resistance for longer life. However, to get the most out of your composite furniture, it's best to check the manufacturer's recommendations on use and maintenance.

Sheet Vinyl

Vinyl flooring or PVC flooring is a type of synthetic flooring. It presents a new and cost-effective alternative to natural floors such as wood, concrete, or marble. Unlike vinyl tiles or planks, sheet vinyl comes as square or rectangular sheets, which can be cut to size to fit the specific dimensions of a room. Sheet vinyl resists moisture, so it is a popular choice for moisture-prone areas such as bathrooms and kitchens. Unlike tiles, these sheets are joint-free, so water can't seep through, offering extreme durability. When the floor underlayment isn't smooth, then you can opt for this kind of flooring material. The flexible sheet vinyl will cover or hide any minor flaws in the subfloor or underlayment. However, its installation isn't easy as it calls for accurate measurements and precise cuts of the sheets. It has to be laid with great care around fixtures, edges, and doorways. Using the right tools is crucial to prevent costly mistakes such as tears or wastage. Seeking out a professional installer will give you the best results.

Vinyl Tiles

Vinyl floors are eco-friendly, easy to maintain, and comfortable to walk on. Modern vinyl floor tile is chosen for heavily used rooms because of its low cost, durability, and easy maintenance. Besides, it is resistant to abrasion and impact and can be refinished again and again with chemical strippers and mechanical buffing equipment. Removing and replacing when damaged is also easy. These Tiles come in a variety of colours and closely resemble wood, stone, or concrete in the finish. Vinyl flooring is one of the first few Eco-friendly resilient floorings in the market.

Maintenance and Care

The most destructive to wood and wood-like materials in the bathroom is moisture. Mould and frost also need to be tackled. Using a waterproofing solution protects against moisture and rot as well as brightens the wood surface. Using a high-quality sealant means you have a protective barrier against moisture. The sealant prevents water from seeping into the furniture, which can cause decay, swelling, warping and reduce its lifespan. It also protects against daily wear as well as UV rays.

Regularly inspecting the bathroom cabinets and bathroom vanity unit will help detect early signs of wear or damage, which can quickly be sorted before the problem becomes impossible to fix. This may mean sanding down rough patches, filling cracks, or applying a coat of sealant. Bathrooms have high humidity and need efficient ventilation to prevent possible damage due to the moist air. A regular maintenance routine will extend the utility value and longevity as well as keep the furniture in prime condition for years.

Conclusion

There are few things in a room that make an impact as big and as instant as the right kind of bathroom furniture. Woods like oak, pine, teak, and mahogany each have a unique character, strength, and aesthetic. However, not all will give you the same degree of moisture resistance, which is paramount for furniture made for bathroom use. The same holds for maintenance needs, plus there is the most vital factor of cost to consider.

Your project is unique, and the material must suit your needs. Visit local showrooms or hardware stores to get a firsthand experience of how the materials look and feel. It's best to consult professionals to get the best advice tailored to your needs. With the right advice and your vision combined, you can find the perfect bathroom furniture pieces that combine utility and durability. Alternatively, you can read our buying guide on bathroom furniture to know about different types of furniture available in the UK Market.